Aluminum Mist Eliminator:

Function & Principle:

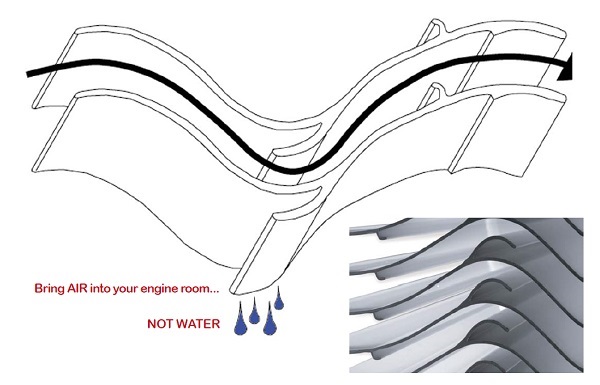

Mist Eliminator is an impingement type separator designed for vertical installation and horizontal airflow. The individual profiles are specially curved and shaped to turn the airflow as it passes over the profile surface. As the entrained liquid droplets have a higher mass than the air, the liquid cannot make the turn as easily as the gas flow,and inertia forces the droplets against the surface of the profile. The liquid forms a film that is pushed along the profile into an area of low pressure located behind the hook. The liquid film is allowed

to coalesce into larger droplets and then drains out via gravity at 90° relative to the airflow. The specially curved shape of the systems moisture eliminator provides a low drag coefficient that allows higher velocities without excessive pressure drop. At higher velocities, smaller drops are removed due to increased inertial forces, and higher efficiencies are achieved.

Application:

Water and salt spray from any ocean platform or vessel are the main source of corrosion. When the salt fog is particularly severe, even fresh water fog can cause corrosion, increasing the workload of maintenance, and may damage machinery, equipments and accessories. Marine steam water separator is the choice of the wave, water vapour, rain, and salt mist that is outside the ventilation system. The Marine steam water separator is designed to operate at a lower pressure, so that the airflow is not overly restrictive, and the machine and equipment will not lack air. It can be made into electric, manual and pneumatic forms, sometimes can replace the watertight louver with cover.

Material:

Aluminum Alloy, Stainless Steel, Galvanized Steel