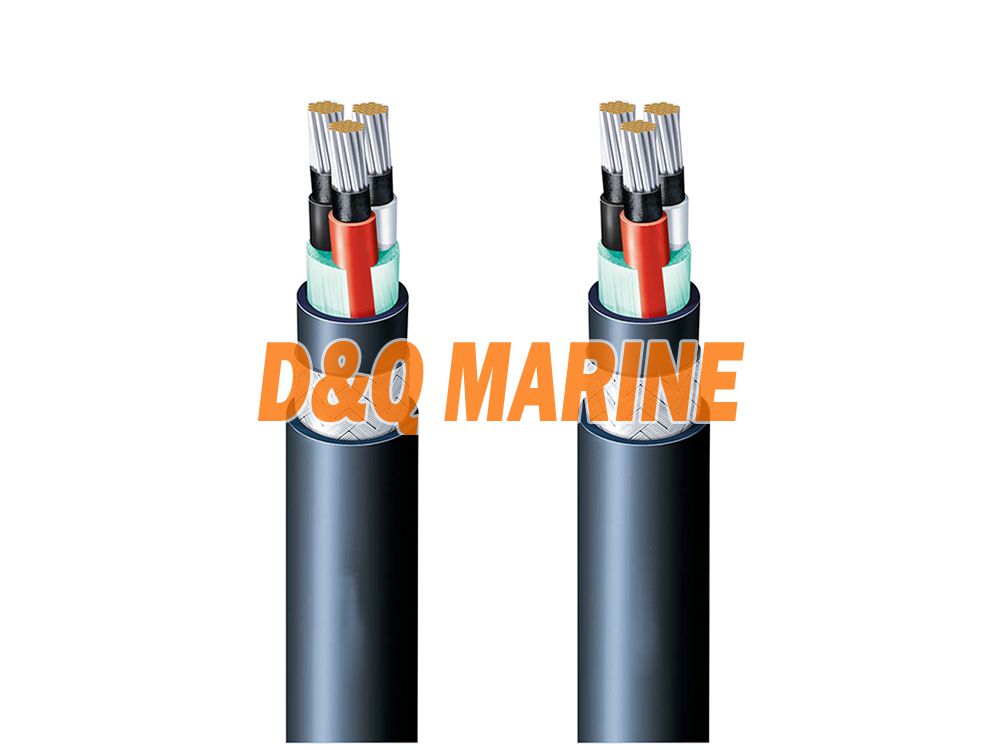

JIS C 3410 0.6/1kV D(T,F,5,6,10)PY, FA-D(T,F,5,6,10)PY Cable:

CABLE DESIGNATION

0.6/1kV D(T,F,5,6,10)PY, FA-D(T,F,5,6,10)PY

0.6/1kV D(T,F,5,6,10)PYC, FA-D(T,F,5,6,10)PYC

0.6/1kV D(T,F,5,6,10)PYCY, FA-D(T,F,5,6,10)PYCY

0.6/1kV D(T)PYE, D(T)PYCE, D(T)PYCYE

APPLICATION STANDARD

- Design guide : JIS C 3410(1999)

- Flame retardant : IEC 60332-1 & IEC 60332-3 Category A (FA-Type)

- Cold bend/impact : CSA 22.2 No. 03 (-35℃ ) (Cold Type)

- Max. conductor temperature : 85℃

TECHNICAL DATA

1. CABLE TYPE: 0.6/1kV (FA-)DPY, 0.6/1kV (FA-)DPYC, 0.6/1kV (FA-)DPYCY

No. of Cores:2 core

Nominal Area(mm2):1.5, 2.5, 4, 6, 10, 16, 25, 35, 50, 70, 95, 120, 150, 185.

2. CABLE TYPE: 0.6/1kV (FA-)DPYE, 0.6/1kV (FA-)DPYCE, 0.6/1kV (FA-)DPYCYE

No. of Cores:2 +Earth core

Nominal Area(mm2):1.5, 2.5, 4, 6, 10, 16, 25, 35, 50, 70, 95.

3. CABLE TYPE: 0.6/1kV (FA-)TPY, 0.6/1kV (FA-)TPYC, 0.6/1kV (FA-)TPYCY

No. of Cores:3 core

Nominal Area(mm2):1.5, 2.5, 4, 6, 10, 16, 25, 35, 50, 70, 95, 120, 150, 185.

4. CABLE TYPE: 0.6/1kV (FA-)TPYE, 0.6/1kV (FA-)TPYCE, 0.6/1kV (FA-)TPYCYE

No. of Cores:3+Earth core

Nominal Area(mm2):1.5, 2.5, 4, 6, 10, 16, 25, 35, 50, 70, 90, 120, 150, 185.

5. CABLE TYPE: 0.6/1kV (FA-)FPY, 0.6/1kV (FA-)FPYC, 0.6/1kV (FA-)FPYCY

No. of Cores : 4 core

Nominal Area(mm2):1.5, 2.5, 4, 6, 10, 16, 25, 35, 50, 70, 95, 120, 150, 185.

6. CABLE TYPE:0.6/1kV (FA-)5PY, 0.6/1kV (FA-)5PYC, 0.6/1kV (FA-)5PYCY

No. of Cores : 5 core

Nominal Area(mm2):1.5, 2.5, 4, 6, 10, 16.

7. CABLE TYPE:0.6/1kV (FA-)6PY, 0.6/1kV (FA-)6PYC, 0.6/1kV (FA-) 6PYCY

No. of Cores : 6 core

Nominal Area(mm2):1.5, 2.5, 4, 6.

8. CABLE TYPE:0.6/1kV (FA-)10PY, 0.6/1kV (FA-)10PYC, 0.6/1kV (FA-)10PYCY

No. of Cores : 10 core

Nominal Area(mm2):1.5, 2.5, 4.

| Classification | Code | Construction Detail | ||

|

Conductor |

D(T,F,5,6,10) | Stranded tinned annealed copper wires as per JIS C 3410. | ||

| Insulation | P | EPR as per JIS C 3410. | ||

| Cabling |

Insulated conductors

shall be cabled. Flame retardant & non-hygroscopic fillers may be used. Suitable tape(s) may be applied on the cabled core. |

|||

| Sheath | Y | PVC as per JIS C 3410. | ||

| Armor | C |

Braid of galvanized

steel wires. Coverage density is minimum 90%. |

||

| Paint |

The white paint shall

be painted uniformly on the steel wire braid Protective covering Type, paint is dispensable. |

|||

| Protective Covering |

PVC as per JIS C

3410. Outer sheath color : Black |

|||

| Core identification | No. of cores | Without Earth core | ||

| 2C | Black, White | |||

| 3C / 2C+E | Black, White, Red | |||

| 4C / 3C+E | Black, White, Red, Green | |||

| 5C and over | Black No. on white insulation | |||