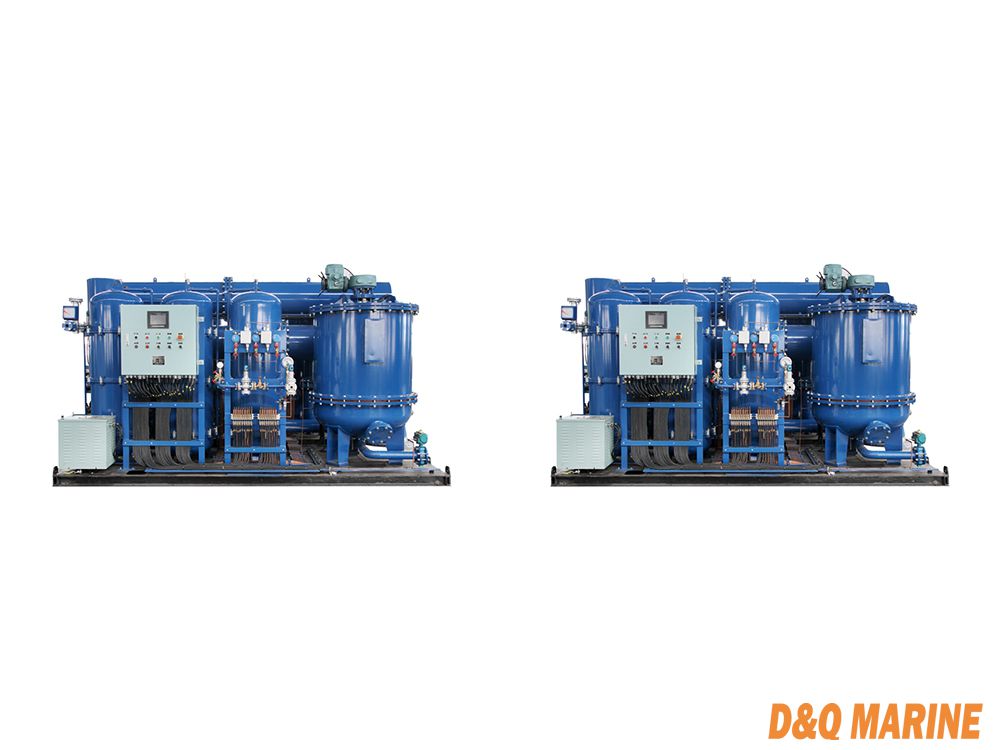

JB Marine Ballast Water Management System:

Description:

Process: "JB ballast water

management system" is our company to meet the rules of IMO, D - 2 and

developed a new system. The

system USES 50 microns section self-cleaning filter first remove bulky

particles, and then by microfiltration membrane to remove all size

microorganisms and bacteria, inert gas, nitrogen at the same time.

Ballast,

ballast water through the filter unit, membrane separation unit, into the

ballast tank after filtration, separation, filling the nitrogen at the same

time, the filtered concentrate directly to the outboard.

Uninstall:

ballast pump will hold ballast water directly to the yard.

Filter

unit: 50 microns filter unit first to remove most of the solid particles and

microorganisms, ballast water is controlled by differential pressure or set a

time to recoil of each stainless steel filter, flushing is accomplished in an

instant, the water consumption, to ensure the processing flow. Rinses the creature into the home port, are not

of the alien species.

Membrane

separation unit + control unit: the company after years of development, has

developed for large flow microfiltration membrane of ballast water treatment,

and adopt various measures to ensure its bigger flux, the life test show that

the membrane life can reach more than 4 years, after the separation unit

treatment of ballast water, more than 10 microns creature is almost zero, and

bacteria, and to ensure that the discharge water quality conform to the

requirements of the D - 2 standard. Control

unit can be automatic and manual control of the whole system, and can real time

record run data, troubleshooting tips and other relevant information.

Nitrogen

making device: nitrogen making device has already been widely used in the oil

tank of oil tanker explosion protection system, especially the relevant

Suggestions, prevent water ballast tank corrosion, it is recommended to use

inert gas protection. Using

PSA alternate adsorption oxygen and nitrogen in the air, concentration can be

as high as 99.99%, and less power consumption.

System

features.

1, in

addition to nitrogen, this system does not add any material, no impact on the

environment.

2,

this system USES modular design, suitable for all kinds of new and old ships.

3,

this system filter unit, the membrane separation unit of backwash water from

its own filtered water, do not need any external water supply.

4,

this system energy conservation province electricity, operation cost is low.

5,

this system filter unit, the membrane separation unit of backwash concentrate

immediate discharge to port waters, very little sediment into the ballast

tanks, can reduce a lot of tank cleaning work.

6,

this system adopts the PSA technology of preparation of pure nitrogen added to

the ballast water chamber, will not change, the water quality does not produce

any secondary substances affect the environment, the crew and the general

public.

Nitrogen

in 7, the system has excellent corrosion protection for ballast bulkhead,

reduce the corrosion of the hull.

8,

this system is easy to operate, low maintenance cost.

Certificate:

now get CCS, BV, LR, NK, ABS, AMS (USCG) certificate.

Technical Data:

| Type | JB-200 | JB-300 | JB-400 | JB-500 | JB-600 | JB-800 | JB-1000 | JB-1200 | ||

| Treat Capacity | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | 1200 | ||

| Filter Unit | Configure Power(kw) | 4.5 | 6 | 6 | 6 | 6 | 11.5 | 11.5 | 11.75 | |

| Outline Dimension | L | 600 | 710 | 760 | 920 | 920 | 1000 | 1250 | 1600 | |

| W | 580 | 680 | 720 | 850 | 880 | 965 | 1150 | 1150 | ||

| H | 1900 | 1950 | 1950 | 2000 | 2000 | 2050 | 2050 | 2310 | ||

| Pressure drop | 0.05Mpa | |||||||||

|

Aperture

of filter candle (um) |

50 | |||||||||

| Membrane Unit | Configure Power(kw) | 3 | 4 | 4 | 5.5 | 5.5 | 5.5 | 7.5 | 11 | |

| Outline Dimension | L | 2150 | 2750 | 2750 | 2850 | 2850 | 2580 | 3650 | 3650 | |

| W | 900 | 1200 | 1200 | 1400 | 1400 | 2200 | 2585 | 2600 | ||

| H | 1700 | 1900 | 1900 | 2350 | 2350 | 2350 | 2350 | 2300 | ||

| Pressure drop | 0.05Mpa | |||||||||

| Nitrogen unit | N2 Concentration | 99% | ||||||||

| N2 flowrate(Sm3/h) | 5.14 | 10.85 | 10.85 | 10.85 | 16.56 | 16.56 | 25.7 | 25.7 | ||

| Outline Dimension | L | 1270 | 1480 | 1750 | 1950 | |||||

| W | 500 | 600 | 600 | 700 | ||||||

| H | 1780 | 1780 | 2020 | 2075 | ||||||

| Configure Power(kw) | 0.4 | 0.5 | 0.9 | 1.2 | ||||||

| Control Unit | Protection Grade | IP44/IP56 | ||||||||

| Outline Dimension | L | 650 | ||||||||

| W | 700 | |||||||||

| H | 250 | |||||||||

| Compressed Air | 0.7Mpa | |||||||||

| Total configure power(KW) | 7.9 | 10.5 | 10.5 | 12 | 12.4 | 17.9 | 20.2 | 23.95 | ||

| Salinity Limitation | No limitation | |||||||||

| Discharge Standard | D-2 | |||||||||

Technical data 2:

| Type | JB-1500 | JB-1800 | JB-2000 | JB-2500 | JB-3000 | JB-4000 | ||

| Treat Capacity | 1500 | 1800 | 2000 | 2500 | 3000 | 4000 | ||

| Filter Unit | Configure Power(kw) | 11.75 | 11.75 | 12.5 | 12.5 | 16.5 | 16.5 | |

| Outline Dimension | L | 1600 | 1650 | 1895 | 1895 | 2100 | 2300 | |

| W | 1400 | 1230 | 1660 | 1670 | 1700 | 2000 | ||

| H | 2150 | 2600 | 2754 | 3125 | 3130 | 3430 | ||

| Pressure drop | 0.05Mpa | |||||||

|

Aperture

of filter candle (um) |

50 | |||||||

| Membrane Unit | Configure Power(kw) | 11 | 11 | 11 | 15 | 15 | 15 | |

| Outline Dimension | L | 4050 | 3200 | 3200 | 3700 | 3970 | 4820 | |

| W | 2850 | 2430 | 2430 | 3100 | 3100 | 2970 | ||

| H | 2650 | 2980 | 3135 | 3135 | 3270 | 3120 | ||

| Pressure drop | ||||||||

| Nitrogen unit | N2 Concentration | |||||||

| N2 flowrate(Sm3/h) | 36.6 | 55 | 55 | 80 | 80 | 110 | ||

| Outline Dimension | L | 1950 | 1800 | 2860 | 2500 | |||

| W | 700 | 1600 | 1100 | 2100 | ||||

| H | 2250 | 2000 | 2200 | 2200 | ||||

| Configure Power(kw) | 1.2 | 1.5 | 2.2 | 3 | ||||

| Control Unit | Protection Grade | IP44/IP56 | ||||||

| Outline Dimension | L | 650 | ||||||

| W | 700 | |||||||

| H | 250 | |||||||

| Compressed Air | 0.7Mpa | |||||||

| Total configure power(KW) | 23.95 | 24.25 | 25 | 29.7 | 33.7 | 34.5 | ||

| Salinity Limitation | No limitation | |||||||

| Discharge Standard | D-2 | |||||||