CLZ Marine Vertical Axial Fan:

Usage:

CLZ marine axial fan is designed primarily for ventilation of cabins, air supply or air exhaust. The delivered air can contain the salt fog or acid vapor from the battery. The temperature of the air can not exceed 50 centigrade degree.

Construction:

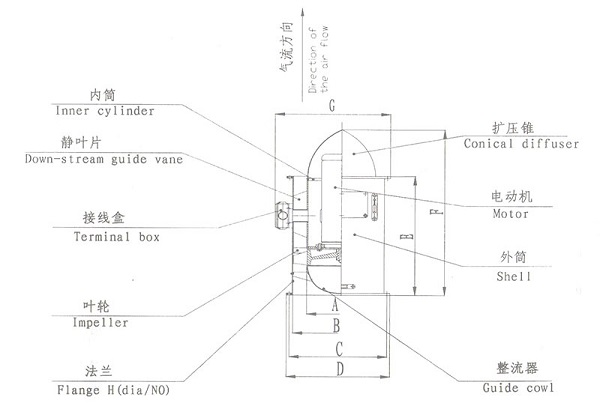

CLZ marine axial fan consists of the impeller, casing, motor, guide cowl, rectifier, etc.

1. Casing is made of steel plate with enough thickness, composed of an inner cylinder, a shell and a down-stream guide vane. The shell is with flanges on the inlet and outlet to connect with the ducts. The inner cylinder and the shell are connected with the down-stream guide vane that is used to guide the air flow.

2.Motor is the special motor manufactured by the professional motor factory. It is totally enclosed, naturally cooled and capable of resisting the salty fog, shocking and vibration. The motor is installed inside of the inner cylinder, the electric motor type are ZZT-H marine electric motor (220V) or Y-H marine electric motor (220V/380V)

3.Impeller is made of anticorrosive casting aluminum alloy,being carefully balanced and mounted directly on the motor shaft extension.

4.The guide cowl is installed on the inlet side, the rectifier is installed on the outlet side. So that the air flow vortex is reduced ,and the fan efficiency is increased. The material of GRP.

5. The guide cowl is installed on the inlet and the conical diffuser is installed on the outlet, the vortex of the air flow is cut and the higher efficiency of the fan is ensured.

6 .The fan is painted by primer painting and the marine painting.

Main Parameter:

| No | Type Form | Capacity (m3/h) | Total Pressure (Pa) | Speed (r/min) | shaft power(kw) | Motor | weight (kgs) | |

| Type | kw | |||||||

| 1 | CLZ1-Z/CLZ1-J | 1600 | 200 | 2900 | 0.142 | ZZT2/30-H | 0.2 | 45 |

| AsH102T2P | 0.25 | 26 | ||||||

| 2 | CLZ2-Z/CLZ2-J | 1600 | 350 | 2900 | 0.219 | ZZT4/30-H | 0.4 | 52 |

| A3H-6322T2 | 0.55 | 32 | ||||||

| 3 | CLZ3-Z/CLZ3-J | 2500 | 300 | 2900 | 0.292 | ZZT4/30-H | 0.4 | 58 |

| A3H-6322T2 | 0.55 | 37 | ||||||

| 4 | CLZ4-Z/CLZ4-J | 2500 | 500 | 2900 | 0.512 | ZZT8/30-H | 0.8 | 78 |

| Y80L1-2-H | 0.75 | 51 | ||||||

| 5 | CLZ5-Z/CLZ5-J | 4000 | 400 | 2900 | 0.63 | ZZT8/30-H | 0.8 | 83 |

| Y80L1-2-H | 0.75 | 53 | ||||||

| 6 | CLZ6-Z/CLZ6-J | 4000 | 700 | 2900 | 1.12 | ZZT15/30-H | 1.5 | 144 |

| Y90S-2-H | 1.5 | 77 | ||||||

| 7 | CLZ7-Z/CLZ7-J | 6000 | 750 | 2900 | 1.53 | ZZT22/30-H | 2.2 | 88 |

| Y90L-2-H | 2.2 | 84 | ||||||

| 8 | CLZ8-Z/CLZ8-J | 9000 | 800 | 2900 | 2.6 | ZZT30/15-H | 3 | 182 |

| Y100L-2-H | 3 | 109 | ||||||

| 9 | CLZ9-Z/CLZ9-J | 12000 | 500 | 1450 | 2.1 | ZZT30/15-H | 3 | 312 |

| Y100L2-4-H | 3 | 170 | ||||||

| 10 | CLZ10-Z/CLZ10-J | 12000 | 900 | 1450 | 3.8 | ZZT55/15-H | 5.5 | 474 |

| Y132S-4-H | 5.5 | 318 | ||||||

| 11 | CLZ11-Z/CLZ11-J | 16000 | 500 | 1450 | 3.3 | ZZT40/15-H | 4 | 358 |

| Y112M-4-H | 4 | 190 | ||||||

| 12 | CLZ12-Z/CLZ12-J | 16000 | 1100 | 1450 | 6 | ZZT75/15-H | 7.5 | 524 |

| Y132M-4-H | 7.5 | 348 | ||||||

| 13 | CLZ13-Z/CLZ13-J | 25000 | 600 | 1450 | 5.2 | ZZT75/15-H | 7.5 | 384 |

| Y132M-4-H | 7.5 | 244 | ||||||

| 14 | CLZ14-Z/CLZ14-J | 25000 | 1100 | 1450 | 10.2 | ZZT130/15-H | 13 | 700 |

| Y160L-4-H | 15 | 459 | ||||||